What are Ultra-Thin Filters?

Visual of filters “flexing” between the gentle force of tweezers

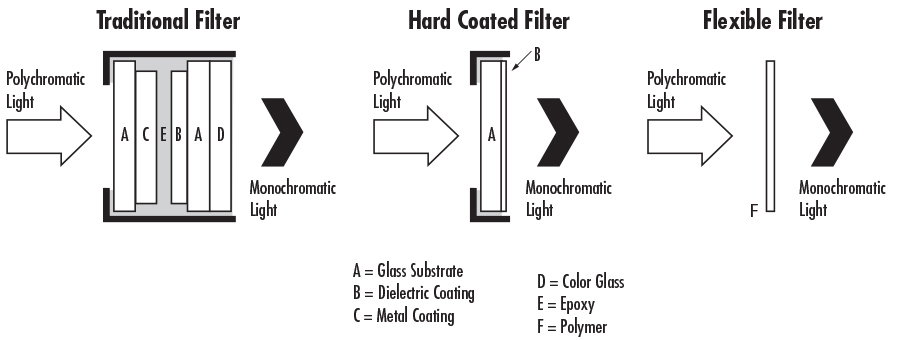

Ultra-Thin Filters are constructed out of flexible polymers and dyes and can bend to conform to both flat and curved shapes. They are resistant to scratches and are as durable as most industry hard oxide coatings. Each filter is comprised of hundreds to thousands of sub-layers. Ultra-Thin Filters can achieve high wavelength selectivity across the visible and near-infrared spectrum and are ideal for high volume applications due to their low cost, light weight, and thin and flexible nature.

The manufacturing process for Ultra-Thin Filters combines the features of optical fiber production and plastic film extrusion to provide precise control of thickness and refractive index. This is needed to create complex multilayer interference filters at costs appropriate for high volume markets where laser damage, thermal drift, and narrower operating temperature ranges are not an issue. Possible application spaces include laser-based multi-photon microscopy, astronomy, fluorescence instrumentation, flow cytometry, and other biomedical laser systems.

Ultra-Thin Filters have a few disadvantages that mostly stem from the polymer substrate. They have a limited operating temperature and should be used within 30˚C of room temperature to prevent damage to the polymer layers structure. For this reason, Ultra-Thin Filters are not recommended for use with laser systems that generate a lot of heat on the surface of an optic. There will also be a small chromatic shift at various angles of incidence due to the ability to flex the filters. Figure 1 below shows an ultra-thin bandpass filter at four angles of incidence ranging from zero degrees (normal incidence) to 45 degrees. Ultra-Thin Filters also have slightly higher wavefront error compared to more rigid glass substrate filters; the thicker the flexible filter, the more rigid it will be and with more rigidity less wavefront error will be present.

The most obvious advantage to Ultra-Thin Filters is that they are bendable and conform to both flat and curved shapes. They are easily cut either by hand with scissors or blades, or in high volume instances with the use of laser cutting equipment. The ultra-thin design minimizes optical path length and eliminates the need for a separate mounting solution for the filter. Featuring a shatter-free all-plastic design, these filters can be produced from very flexible options that are less than 100µm thick to more rigid options that are roughly 500µm thick.

Key Features Include:

- Flexible Material Design

- 350nm to 1600nm Spectral Range

- Notch, Edge, and Bandpass Filter Design Capabilities

- Multi-Notch and Multi-Bandpass Filters Available

- Scratch Insensitive

- OD 2 Absolute Design, OD 4 Blocking Achievable

- >90% Achievable Transmission

- Ultra-thin Design (300-500µm Thickness)

Figure 1: Effects on AOI Shift on Filter Reflectivity

| Traditional Filter | Hard Coated Filter | Ultra-Thin Longpass Filters | |

|---|---|---|---|

| Substrate: | Stack of Glass, Metal, Plastic | Single Piece of Glass | Stack of Ultra-Thin Polymers |

| Transmission (VIS only): | 75% (approx.) | >90% | >90% |

| Clear Aperture: | >80% | >80% | >90% |

| Thickness: | 5mm | >1mm | 200 - 500µm |

| Blocking, Optical Density: | >OD 4 average | >OD 6 absolute | >OD 4 average |

| Temperature Stability: | Medium | High | Medium |

| Cut-on Steepness: | >3% | <1% | 2% |

| Cut-on Tolerance: | >3% | <1% | 2% |

| Price: | $$ | $$$ | $ |

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023, Edmund Optics Inc., 101 East Gloucester Pike, Barrington, NJ 08007-1380 USA

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act