What is SWIR?

Short-wave infrared (SWIR) light is typically defined as light in the 0.9 – 1.7μm wavelength range, but can also be classified from 0.7 – 2.5μm. Since silicon sensors have an upper limit of approximately 1.0μm, SWIR imaging requires unique optical and electronic components capable of performing in the specific SWIR range. Indium gallium arsenide (inGaAs) sensors are the primary sensors used in SWIR imaging, covering the typical SWIR range, but can extend as low as 550nm to as high as 2.5μm. Although linear line-scan inGaAs sensors are commercially available, area-scan inGaAs sensors are typically ITAR restricted. ITAR, International Treaty and Arms Regulations, is enforced by the government of the United States of America. ITAR restricted products must adhere to strict export and import regulations for them to be manufactured and/or sold within and outside of the USA. Nevertheless, lenses such as SWIR ones can be used for a number of commercial applications with proper licenses.

Figure 1: Electromagnetic Spectrum Illustrating SWIR Wavelength Range

WHY USE SWIR?

Unlike Mid-Wave Infrared (MWIR) and Long-Wave Infrared (LWIR) light, which is emitted from the object itself, SWIR is similar to visible light in that photons are reflected or absorbed by an object, providing the strong contrast needed for high resolution imaging. Ambient star light and background radiance (nightglow) are natural emitters of SWIR and provide excellent illumination for outdoor, nighttime imaging.

It is essential to use a lens that is designed, optimized, and coated for the SWIR wavelength range. Using a lens designed for the visible spectrum will result in lower resolution images and higher optical aberrations. Since SWIR wavelengths transmit through glass, lenses, and other optical components (optical filters, windows, etc.) designed for SWIR can be manufactured using the same techniques used for visible components, decreasing manufacturing cost and enabling the use of protective windows and filters within a system.

A large number of applications that are difficult or impossible to perform using visible light are possible using SWIR. When imaging in SWIR, water vapor, fog, and certain materials such as silicon are transparent. Additionally, colors that appear almost identical in the visible may be easily differentiated using SWIR.

SWIR APPLICATIONS

SWIR imaging is used in a variety of applications including electronic board inspection, solar cell inspection, produce inspection, identifying and sorting, surveillance, anti-counterfeiting, process quality control, and much more. To understand the benefits of SWIR imaging, consider some visual examples of common, everyday products imaged with visible light and with SWIR.

ROLL OVER to See SWIR Image

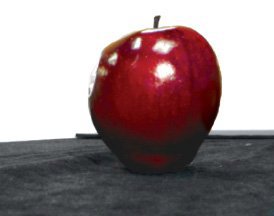

Figure 2a: Visible Imaging of Red Apple. Notice the Apple Looks Perfectly Red with Visible Imaging. Defects are Not Easily Discernable.

ROLL OVER to See SWIR Image

Figure 2b: SWIR Imaging of Red Apple. Bruising is Clearly Evident on the Apple with SWIR Imaging. It is Easy to Inspect Any Defects on the Skin.

ROLL OVER to See SWIR Image

Figure 3a: Visible Imaging of Baby Powder Bottle. Notice the Bottle Looks White and Glossy with Visible Imaging. The Powder within is not Discernable at All.

ROLL OVER to See SWIR Image

Figure 3b: SWIR Imaging of Baby Powder Bottle. The Bottle is Transparent to SWIR Wavelengths. It is Easy to See the Amount of Powder Within.

ROLL OVER to See SWIR Image

Figure 4a: The Last Judgment by Jan Provost and imaged in the SWIR waveband by the Detroit Institute of Arts details the artist's original intention by carefully examining the underdrawing which lies beneath the paint film. Image copyright by Detroit Institute of Arts. Used with permission.

ROLL OVER to See SWIR Image

Figure 4b: One can see 10 trumpets underneath the archangel versus the 5 trumpets that were actually painted. The placement of the painted trumpets appears to have necessitated a reposition of the sailing vessel. The toes on top of the globe were also not painted in the same location as the original underdrawing. Image copyright by Detroit Institute of Arts. Used with permission.

ROLL OVER to See SWIR Image

Figure 5a: Bountiful Fruit painted by Philadelphia artist Nicole Koenitzer details the planning process of an artist when creating an oil painting. By examining the painting in the SWIR waveband one can follow the artist's thought process from initial sketch to painting and refinement of finished work.

ROLL OVER to See SWIR Image

Figure 5b: As you can see, the painting originally included bananas and a frame that were omitted from the final image. Along the lower right there appears to be blotches of paint not seen in the visible waveband. Perhaps the artist began painting the background with different materials or changed her mind and touched up the painting at a later date.

Short-wave infrared (SWIR) defines a specific wavelength range over which optical and electronic components are designed and coated. SWIR imaging offers a number of advantages compared to visible when used for inspection, sorting, surveillance, quality control, and host of other applications. It is important to choose components specifically designed, optimized, and coated for the SWIR wavelength range to ensure the highest resolution and lowest aberrations. Manufacturers like Edmund Optics are experienced in designing, manufacturing, and coating SWIR Series lenses. Edmund Optics offers lens assemblies designed with glasses that are optimized for performance in the SWIR spectrum, and anti-reflection (AR) coatings for SWIR specially designed for maximum transmission of SWIR wavelengths. View the SWIR Imaging Applications page to learn more about what Edmund Optics can do for you and answer the question "Can You See Beyond the Visible?"

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023, Edmund Optics Inc., 101 East Gloucester Pike, Barrington, NJ 08007-1380 USA

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®